Embed Frames Products

Product Overview

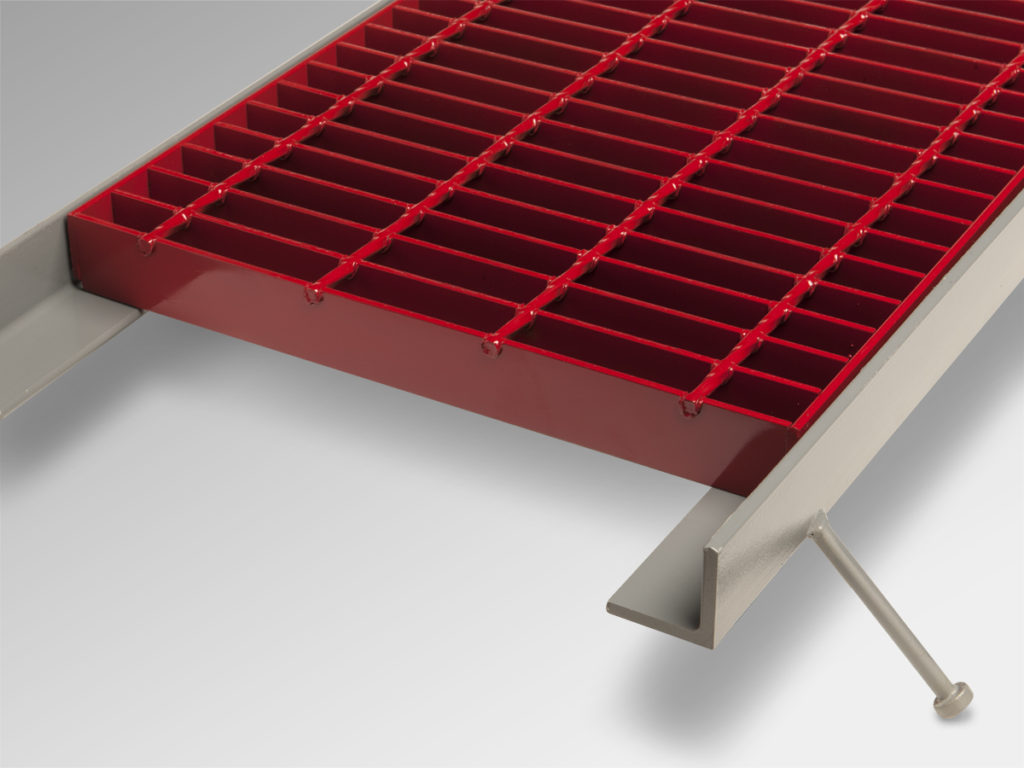

Embed frames, cast into concrete floors and substructures, form a rigid shield for concrete lead edges and perimeters that are subject to cracking and chipping when unprotected.

During construction, these rigid (1/4″ minimum thickness) frames expedite forming and help assure an accurate concrete pour. Upon installation, frames serve as a uniform bearing surface for grates or covers to limit rocking or irregular elevations.

Embed Frames Product Details

E-Z Pour Frames

Grating Pacific E-Z Pour frames are designed to expedite the forming process and provide superior concrete embedment.

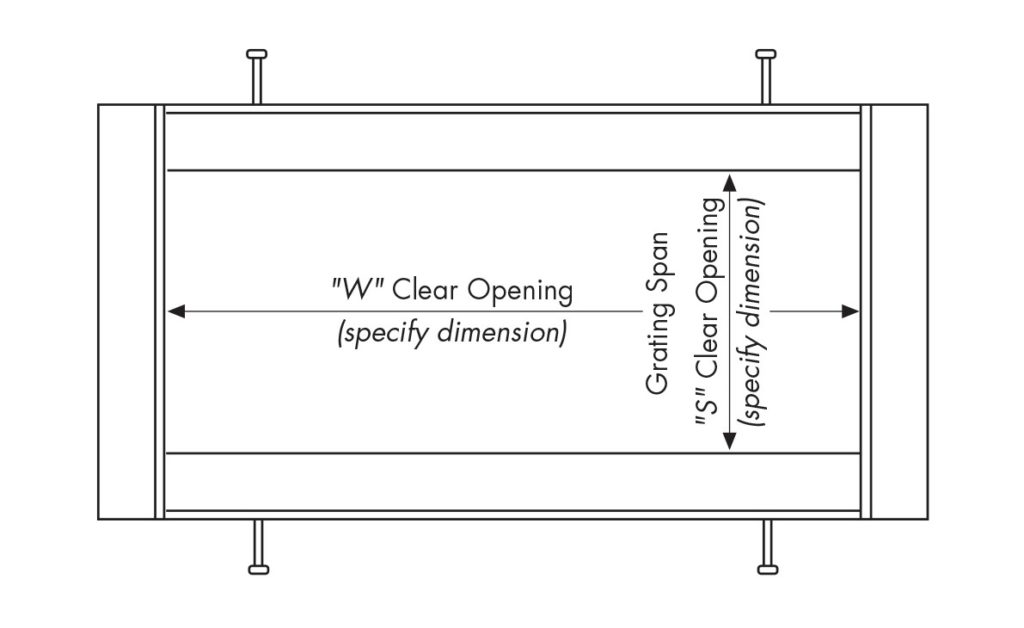

Assembled with continuous anchors on the non-bearing sides, E-Z Pour frames install quickly and provide superior drainage. When specifying, indicate the clear opening dimensions, “W” (width) and “S” (span).

Nail holes are optional and must be specified if desired.

Welded Frames

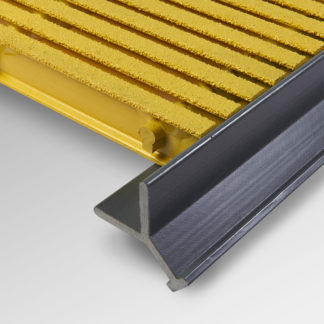

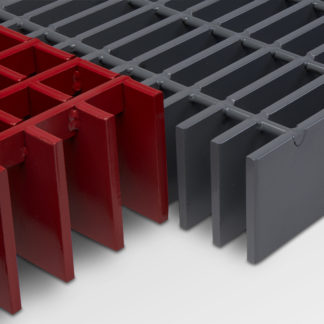

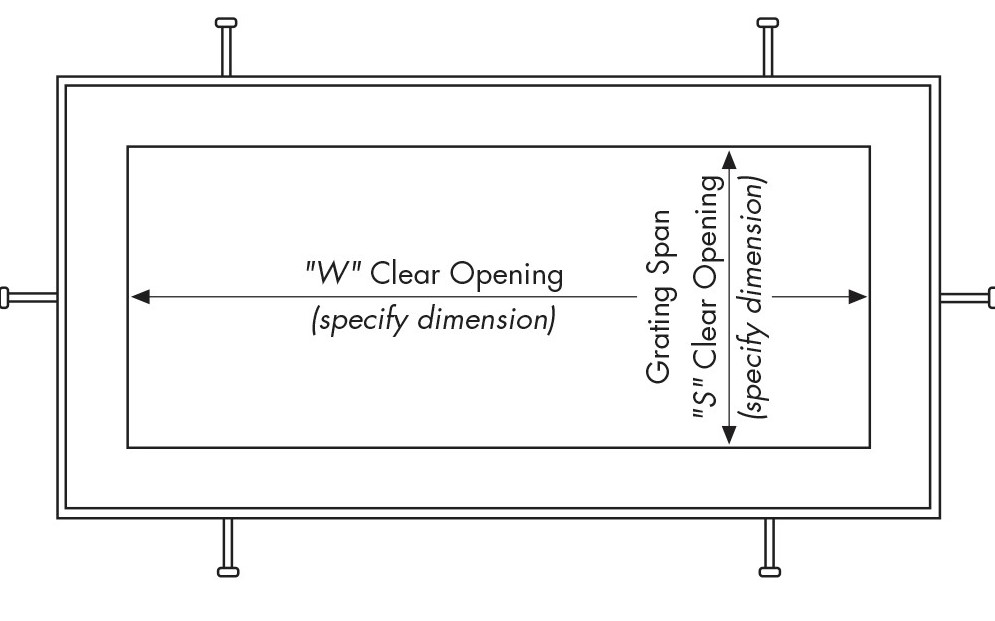

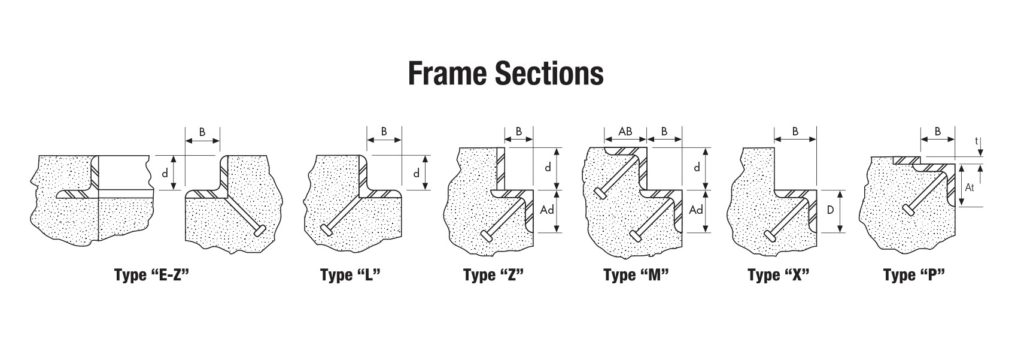

All frames are available in four-sided, one-piece, welded construction units that can accommodate any clear opening. Various frame sections (illustrated below) provide assorted options for edge protection.

Simply specify the desired frame section, clear opening (“W” and “S” dimensions), and desired grating or cover thickness.

Nail holes are optional and must be specified if desired.

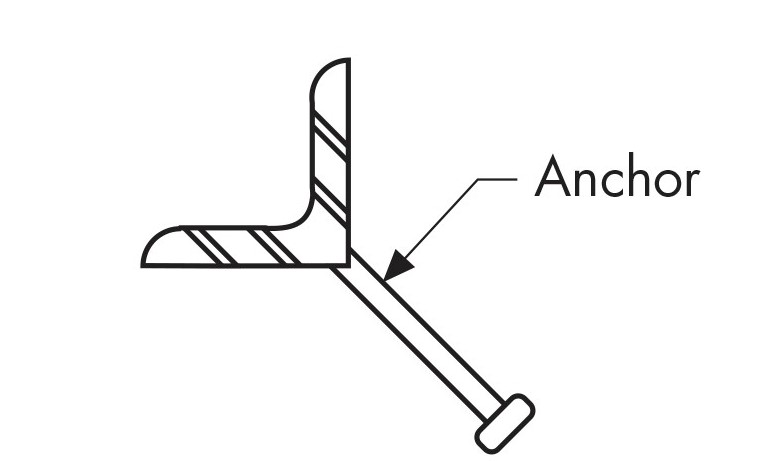

Anchors

All frames are provided with standard 3/8″ x 4″ headed concrete stud anchors welded within 6″ of each end and at a maximum of 24″ on center. Alternative anchor sizes and spacings may be specified.

Materials & Finishes

Carbon steel frames are manufactured with one of three standard finishes, bare steel (no finish), painted, or hot dip galvanized, after fabrication. Aluminum frames are provided mill finish and can be specified with bituminous coating on surfaces to be cast in concrete. Stainless steel frames are supplied mill finish and can be specified as abrasive blasted after fabrication to provide a uniform matte finish.