Product Overview

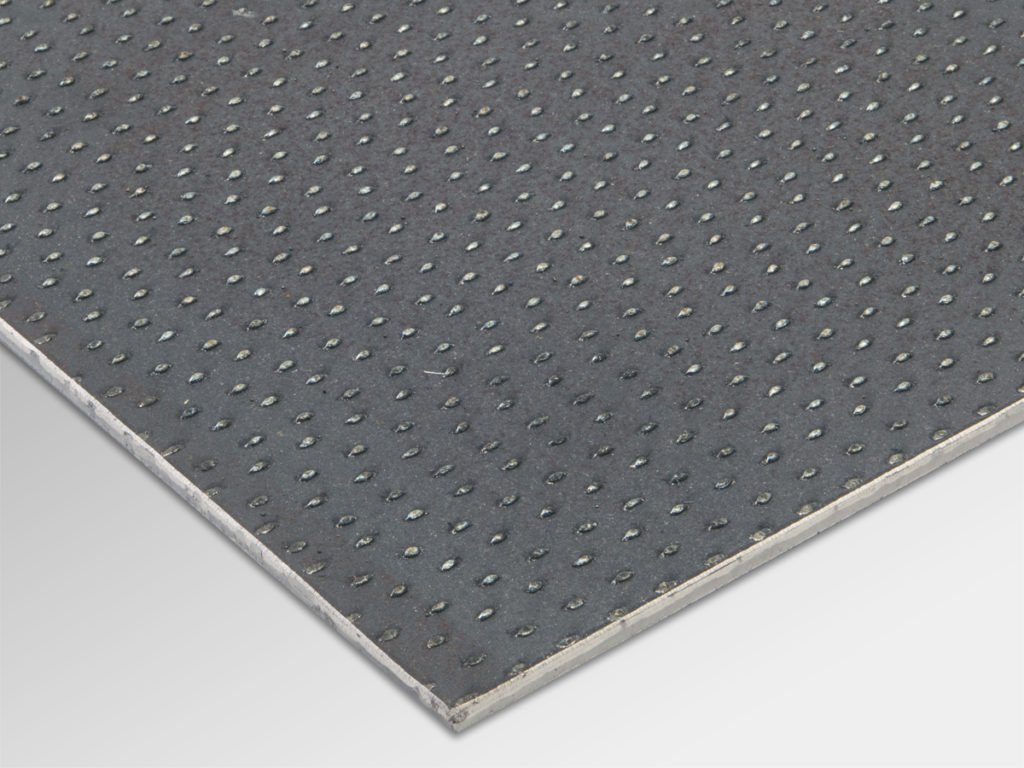

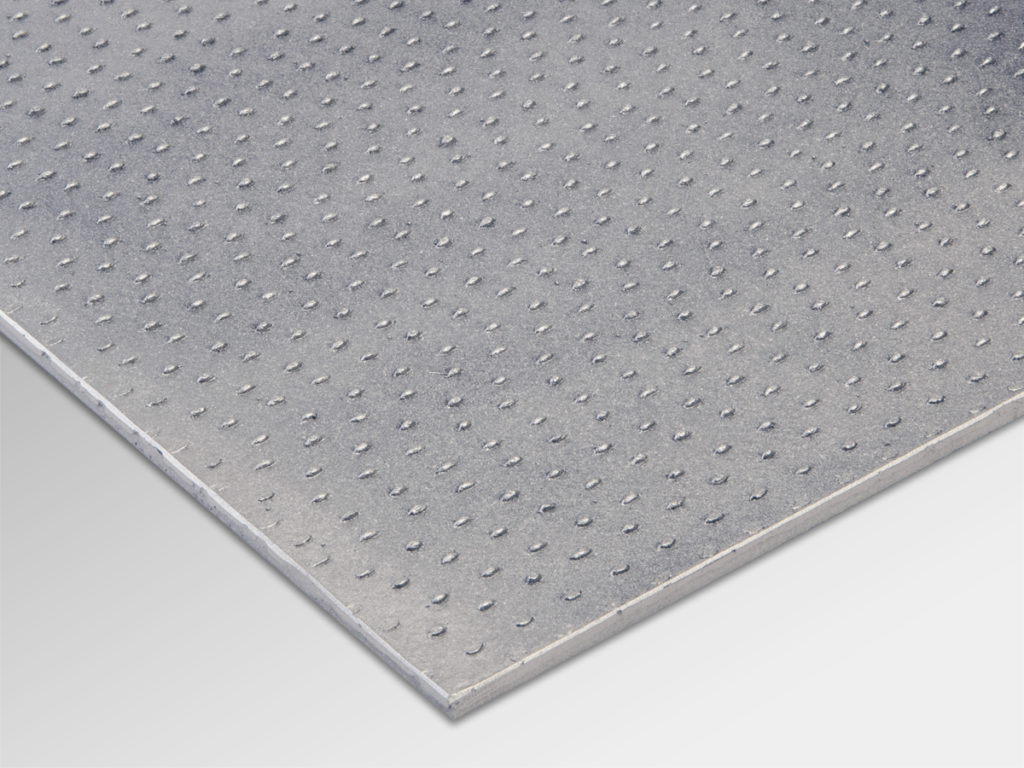

Algrip plate products have efficiently served industry for over 50 years. When work areas are subject to the accumulation of moisture, fluids or lubricants, Algrip is your number one choice! The slip-resistant properties of Algrip Floor Plate provide continuing worker safety in the automotive, petrochemical and food processing industries, just to name a few.

Beyond industrial applications, Algrip Slip-Resistant Floor Plate has experienced increased popularity in commercial applications. To meet the slip-resistance requirements of the Americans with Disabilities Act (ADA), Algrip is commonly specified for inclined ramps and utility vault covers. Please view our Investment in Safety details for further information.

Algrip Slip-Resistant Floor Plate Details

Materials

Stainless Steel

Popular in food processing and clean room environments. Manufactured with ASTM alloy 304 or 316 sheet or plate. Virtually maintenance-free, these products provide unsurpassed slip resistance in areas subject to the accumulation of moisture or debris and comply with FDA and USDA regulations.

Carbon Steel

Manufactured with ASTM A-1011 sheet or plate for pedestrian applications and ASTM A-36 plate for structural applications. Carbon steel products can be provided with a mill finish, painted or hot dip galvanized after fabrication.

Aluminum

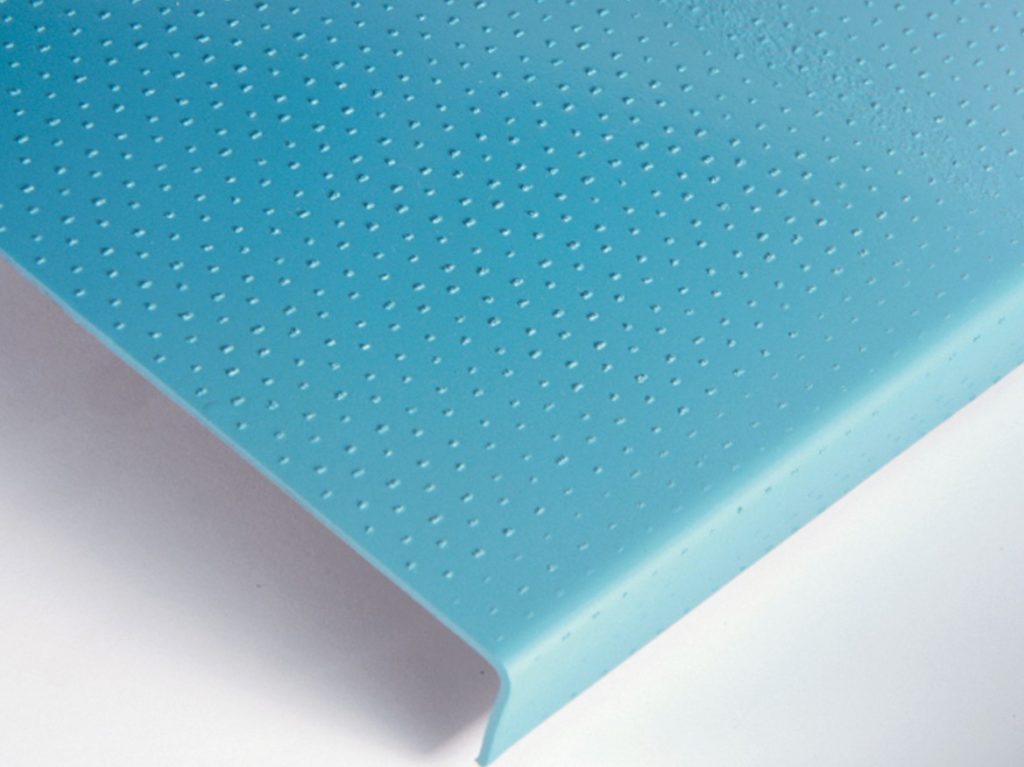

Lightweight and corrosion resistant, plate products are available in alloys 3003 or 5052 per ASTM B-209. Aluminum products are typically provided mill finish.

Durability

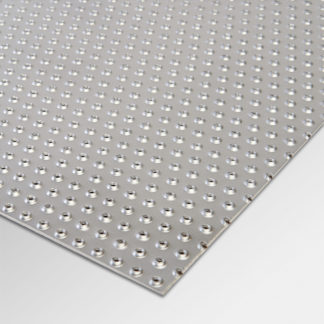

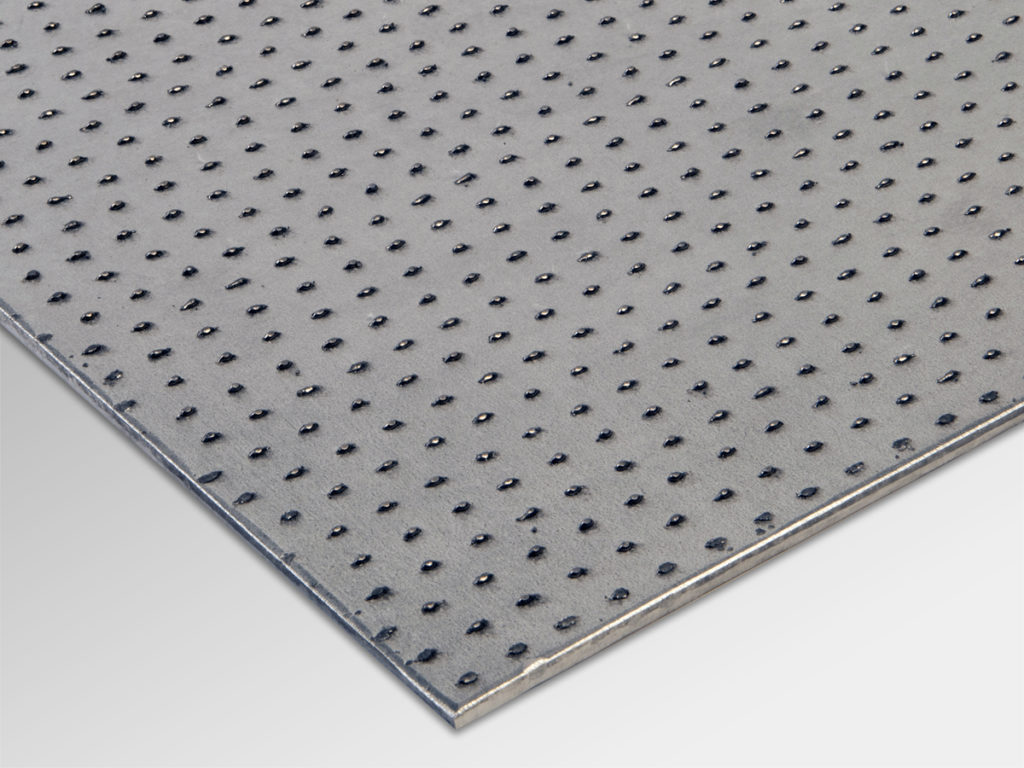

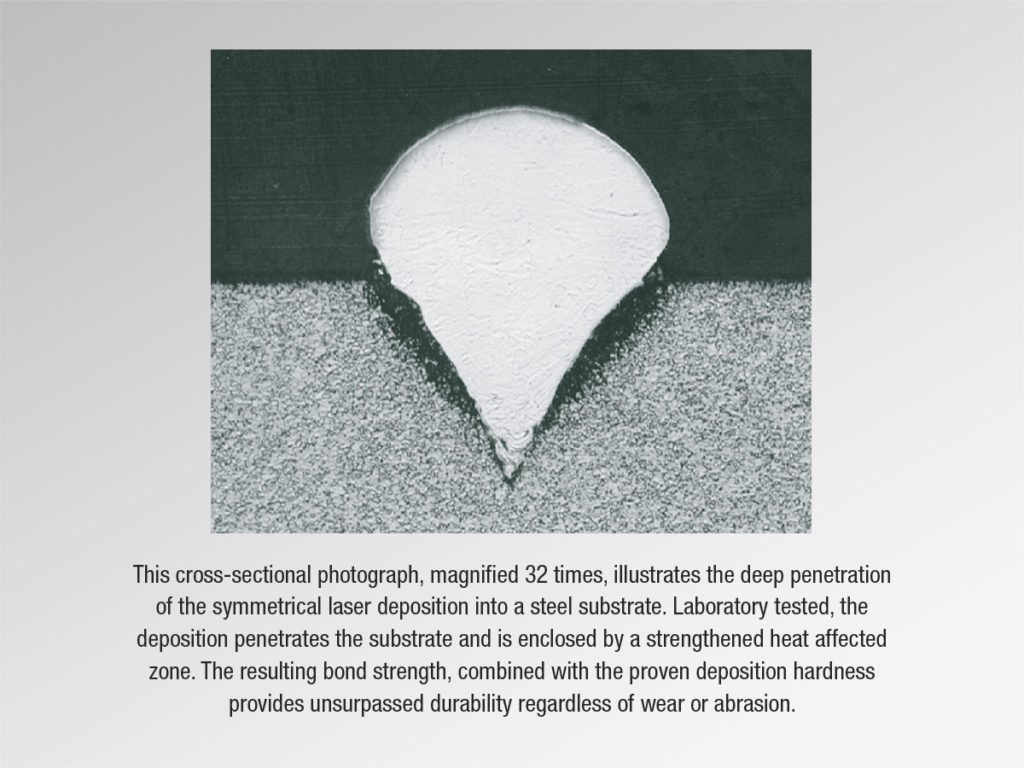

While selection of the appropriate material is important, the true life cycle of safety flooring is commonly determined by the durability of the slip-resistant properties of the walking surface. The traction providing laser depositions of Algrip Flooring Products have been tested for hardness and adherence by independent testing laboratories. The results of these tests assure that Algrip will provide unsurpassed service life.

Laboratory analysis has measured the hardness of Algrip traction providing custom alloy laser depositions at up to 60 on the Rockwell C Scale. Under repetitious pedestrian and vehicular traffic, these deposits will provide continuous, safe, effective service.

Safety

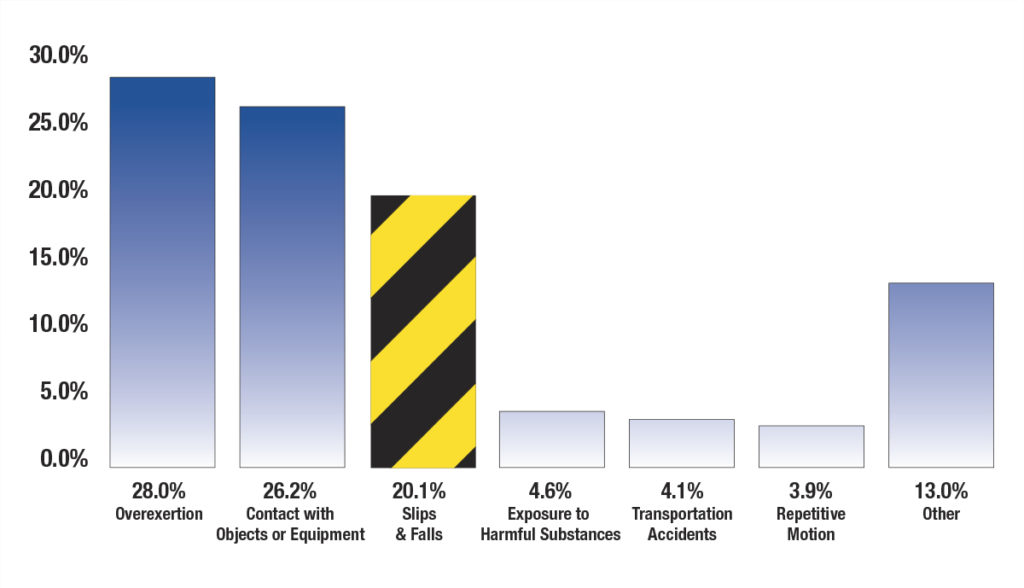

The United States Bureau of Labor Statistics reports that over 20% of all compensable industrial injuries result from slips and falls. Often these accidents occur when liquids, lubricants or foreign materials have accumulated on floors, stairs or work platforms.

For these challenging applications, the unique matrix application of Algrip laser deposits provides unparalleled slip resistance in all directions. Plate products are manufactured with more than 1,000 deposits per square foot. Shoe and tire materials completely encircle and “grab” the deposits. Worker safety and employer protections are significantly enhanced with each installation of Algrip.

How to Specify

Floor plate shall be Algrip Slip-Resistant Floor Plate by Grating Pacific, Inc. 3651 Sausalito Street, Los Alamitos, CA, (800) 321-4314. Slip resistant surface shall be applied by CNC laser deposition process incorporating no less than 1,000 deposits per square foot. Deposits are to penetrate the metal substrate to produce a permanent bond. Static coefficient of friction shall be tested to exceed 0.80 COF for both wet and dry conditions.

Alloy of base material shall be A-1011 Carbon Steel (or A-36 Carbon Steel, 3000 Series Aluminum, or 300 Series Stainless Steel). Material shall be 1/4″ thick (specify from 14 gauge to 1-1/2″ thick). Material shall be finished by Hot Dip Galvanizing (bare steel, painted or galvanized for carbon steel products, mill finish for aluminum or stainless steel products).

Algrip Floor Plate Load Tables

Algrip Fabrication Options

One of the great advantages of Algrip Slip-Resistant Floor Plate is that it can be easily fabricated into finished components using common metal working tools. The superior bond strength of the Algrip slip-resistant surface allows the plate to be fabricated by:

Punching & Drilling

When the plate must be removable, Algrip is easily punched or drilled to accommodate fastening devices or bolted installation.

Welding

Both the top traction surface and the bottom bearing surfaces can be easily welded without damaging the slip-resistant walking surface.

Forming

The excellent adhesion of the skid resistant deposits allow for clean forming of the plate without cracking or delaminating the traction surface.

Countersinking

Common metalworking tools can be used to countersink the Algrip substrate. Countersunk fastening eliminates potential tripping hazards created by protruding fastening devices.

Shearing

Algrip can be fabricated to size by economical mechanical shearing without cracking or damaging the safety providing traction surface.

Flame Cutting

Intricate or radial cuts are easily accomplished using oxygen-acetylene or plasma gas cutting tools.

Finishing & Maintenance

The durable base substrate of carbon steel Algrip and the inert properties of the slip-resistant custom alloy laser deposits readily accept traditional metal finishes without compromising the superior traction properties of the plate. Algrip products can easily be finished with paints or powder coating. Hot dip galvanizing can be accomplished without sandblasting or other expensive surface preparation. Aluminum and Stainless Steel products typically require no finishing after fabrication.

Maintenance concerns are limited to proper cleaning of dirt and debris from the flooring. With a combination of Algrip and proper housekeeping procedures you will continually place your employees on safe footing!

Investing in Algrip is Investing in Safety

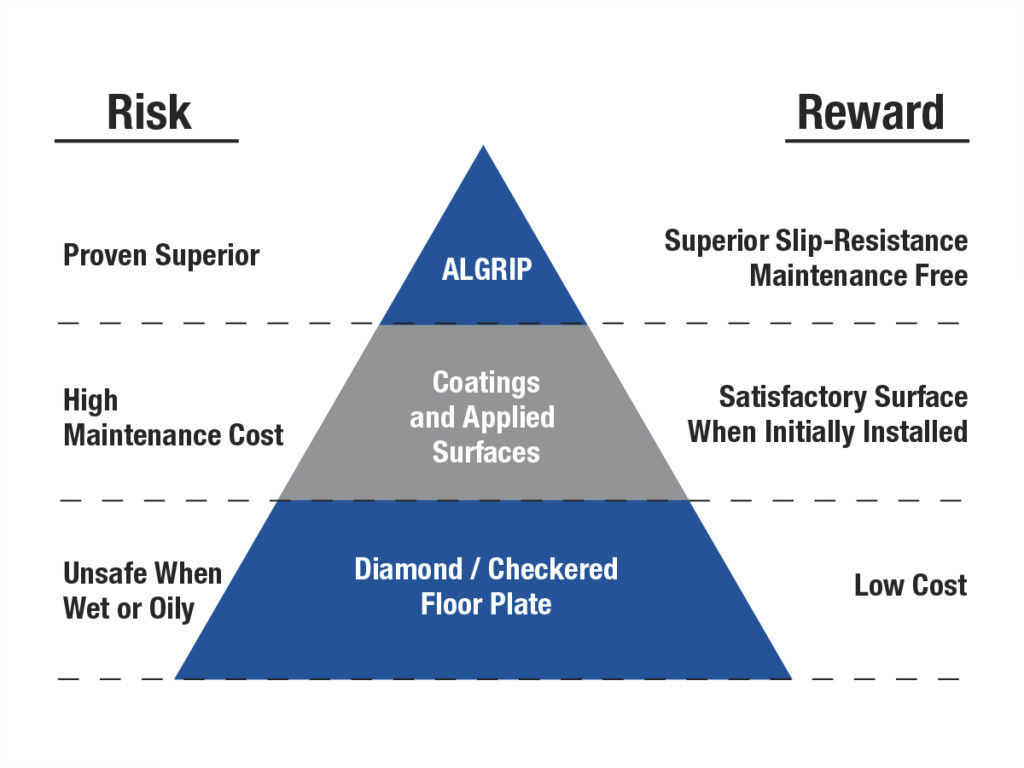

Risk-Reward Analysis

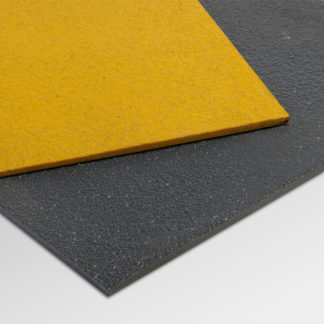

When considering any investment, there are options. Safety flooring products are no exception. The risk-reward pyramid for safety flooring starts with common diamond/checker floor plate. This product is inexpensive, but provides little or no safety when wet or oily. The cost is low, but the risk is high.

The second level of the pyramid relates to floors that have been treated with coatings or applied surfaces. These hybrids provide a fair level of safety when initially installed but often create a maintenance burden. When subjected to wear, applied coatings can quickly deteriorate. Applied surfaces can crack or de-laminate when subjected to service loads. To maintain safe working conditions with these products, there is often a continuous and costly maintenance cycle.

When you invest in Algrip, you have selected a superior safety floor surface that is virtually maintenance free. Once installed, employees and employers are provided the highest level of protection from slips and falls. Supervisors can focus their attention on smooth plant operations rather than recurring maintenance. With Algrip, you are at the Top of the Pyramid!

Return on Investment

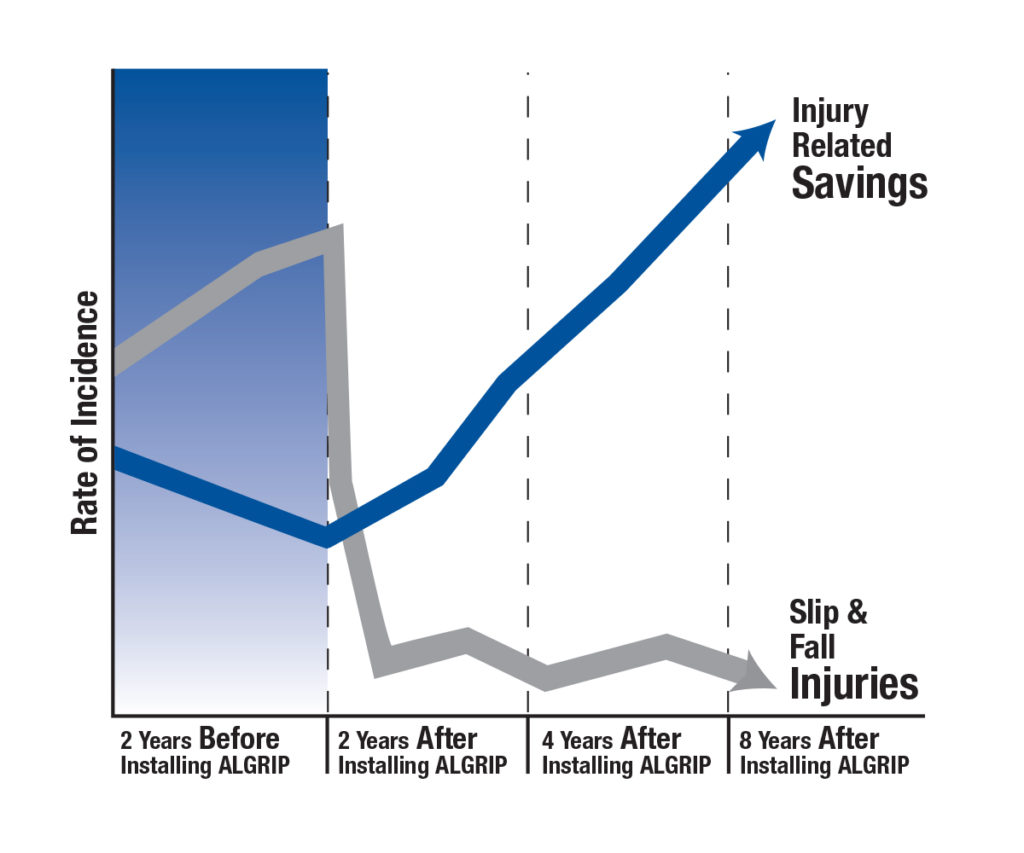

Positive returns are rarely guaranteed on any investment. However, the long-term benefits provided by Algrip Slip-Resistant Flooring products are undeniable.

Beyond maintenance, the greatest return on your Algrip investment stems from a reduction in work-related slip and fall injuries. When workers are provided with this additional protection, there is often a significant reduction in slip and fall injuries. This drop in incidence directly enhances worker productivity, increases injury related savings and effectively increases bottom line performance!

Algrip Slip-Resistant Safety Floor Plate

Related Products

Contact Us

Email: sales@gratingpacific.com

Call: (800) 321-4314