High Load Capacity Fiberglass Grating

Product Overview

Ideal for trench covers, ramps, or inlet covers, high load capacity (HLC) fiberglass grating is produced in both molded and pultruded configurations. These products are engineered and manufactured to support vehicular and forklift traffic in corrosive environments. All high load panels have a Class 1 Fire Rating with an ASTM E84 flame spread rating of 25 or less. Like other fiberglass grating products, these panels are:

- Corrosion resistant

- Low maintenance

- Slip-resistant

- Non-conductive

HLC Fiberglass Grating Products

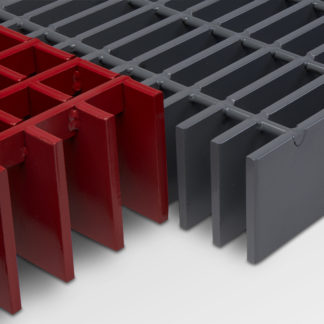

Molded HLC Fiberglass Grating

Manufactured with a 1” x 2” rectangular mesh, molded HLC products are available in 1-1/2” or 2” depths. The 48% open area of these products assures rapid draining of liquids and spills. Standard resin is Vi-Corr vinyl ester, with options for Corvex polyester or FGI-AM food grade.

- Standard panel sizes: 6’ x 4’ and 4’ x 8’

- Standard color: dark gray

- Standard surface: Concave meniscus (optional applied grit)

For additional information view Molded HLC Details & Load Tables.

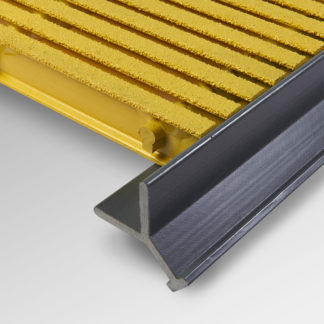

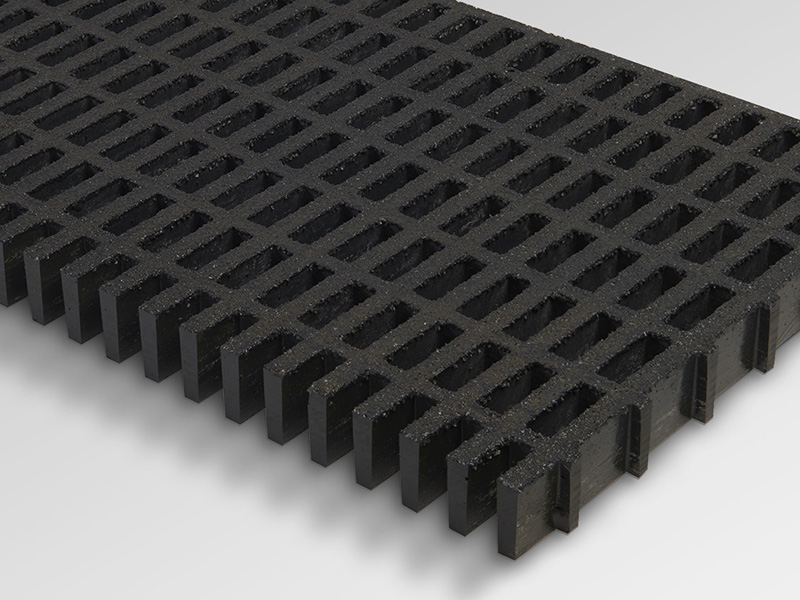

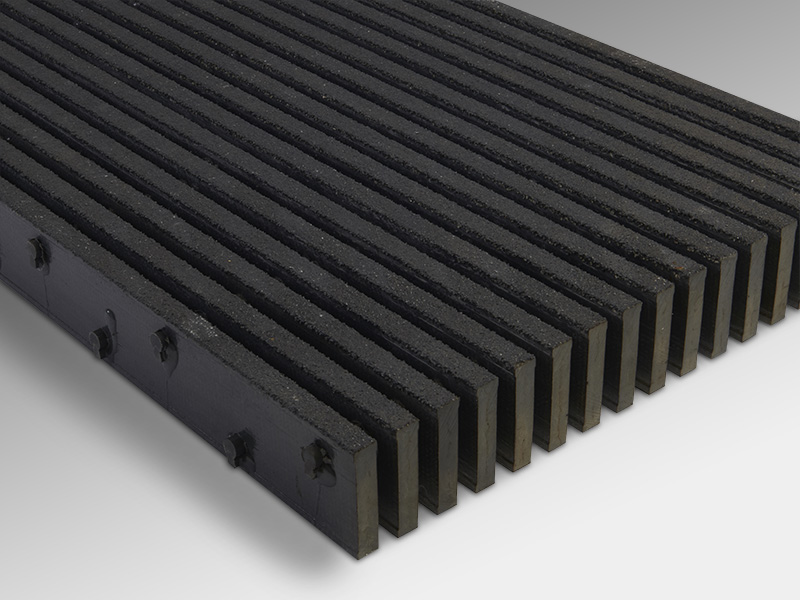

Safe-T-Span Pultruded HLC Grating

Produced in depths ranging from 1” to 3” with open area ranging from 37% to 58%, pultruded HLC products are rated for loads up to H-20 truck traffic. Standard resin is VEFR vinyl ester or optional ISOFR polyester resin.

- Standard panel sizes: 3’, 4’, or 5’ widths, lengths up to 24’

- Standard color: dark gray

- Standard surface: applied grit

For additional information please view Pultruded HLC Grating Details & Load Tables.