Technical Information

Expanded Metal Terminology

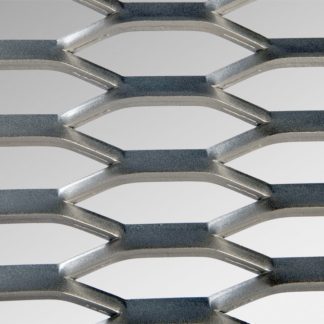

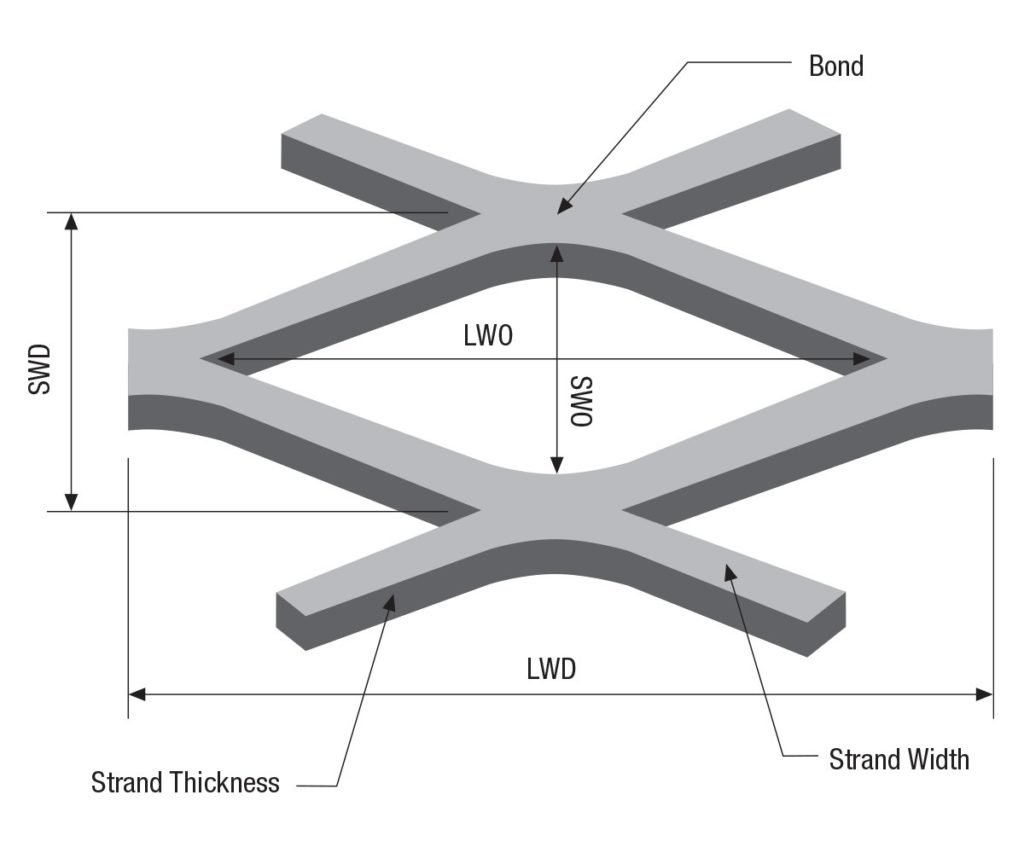

Diamond: The open area formed by stands and bonds.

Strand: The single metal strip that forms the perimeter of the diamond.

Bond: The point where adjacent strands meet.

LWD: Long way of the diamond, the distance from the center of one bond to the center of the next bond across the longer opening of the diamond.

SWD: Short way of the diamond, the center-to-center distance between bonds across the narrow opening of the diamond.

LWO: Long way of the opening, the clear opening of the diamond in the long direction of the diamond.

SWO: Short way of the opening, the clear opening of the diamond across the short direction of the diamond.

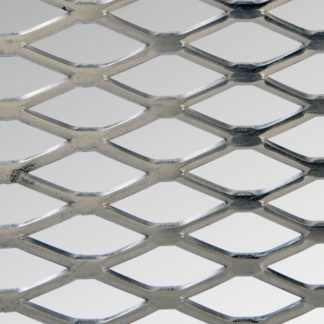

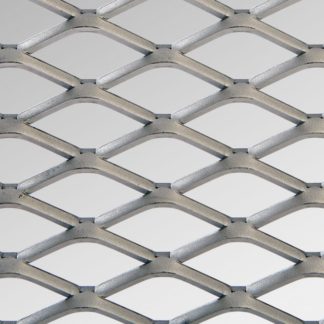

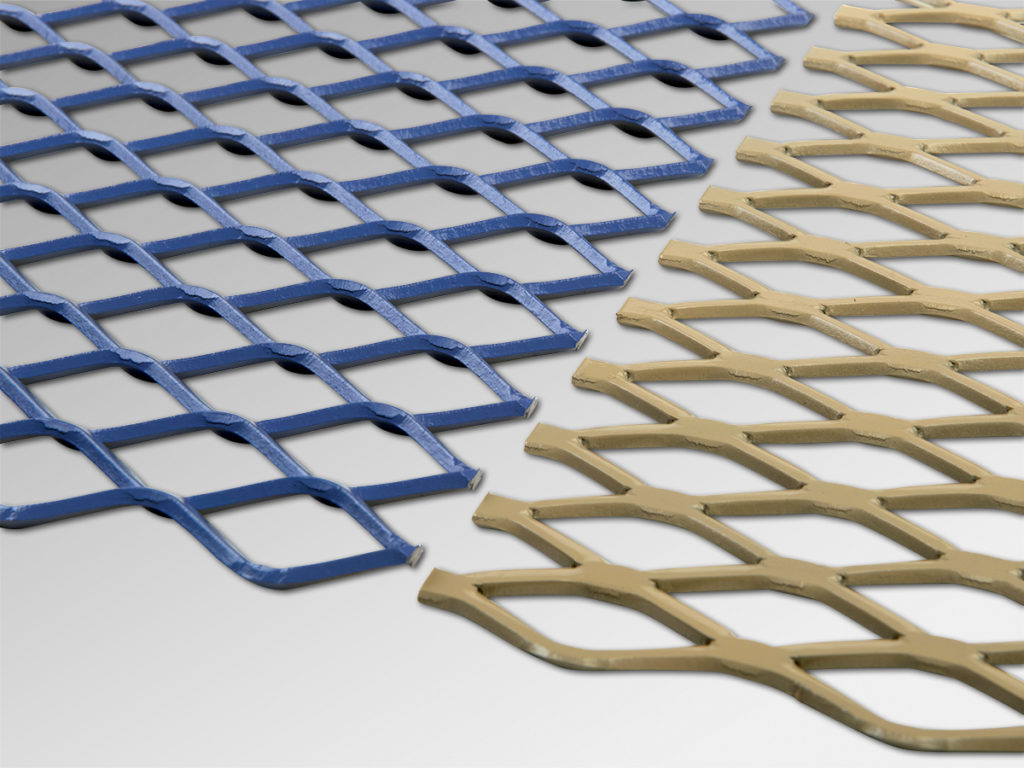

Regular vs. Flattened Expanded Metal

Regular or Standard expanded metal is raised at the bonds of the diamond.

Flattened expanded metals has been passed through rollers and is smooth across each bond.

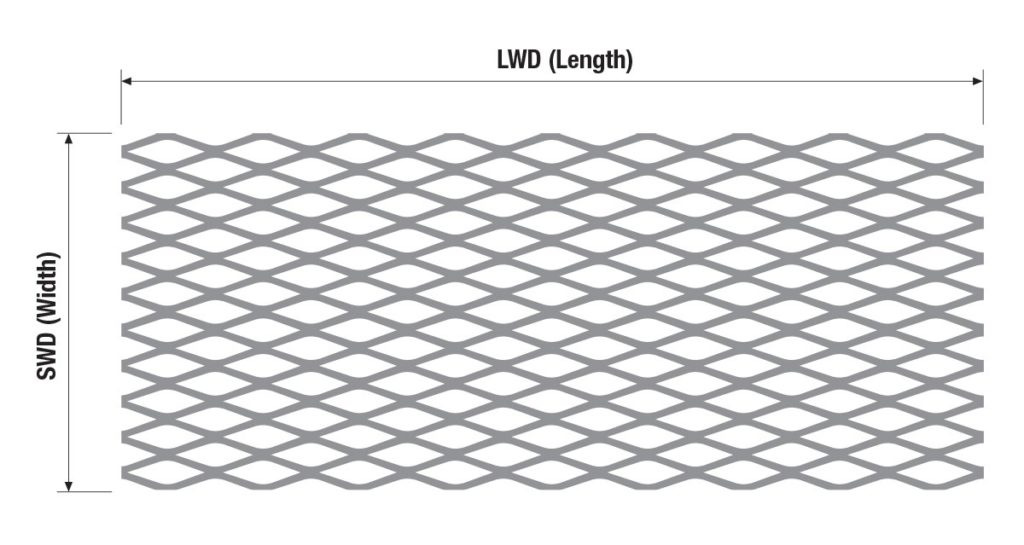

Pattern Orientation

Standard Flow: Pattern runs with the LWD running the length of the sheet and the SWD running across the width of the sheet.

Reverse Flow: Pattern runs with the LWD running across the width of the sheet and the SWD running the length of the sheet.

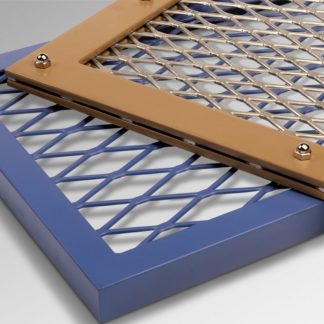

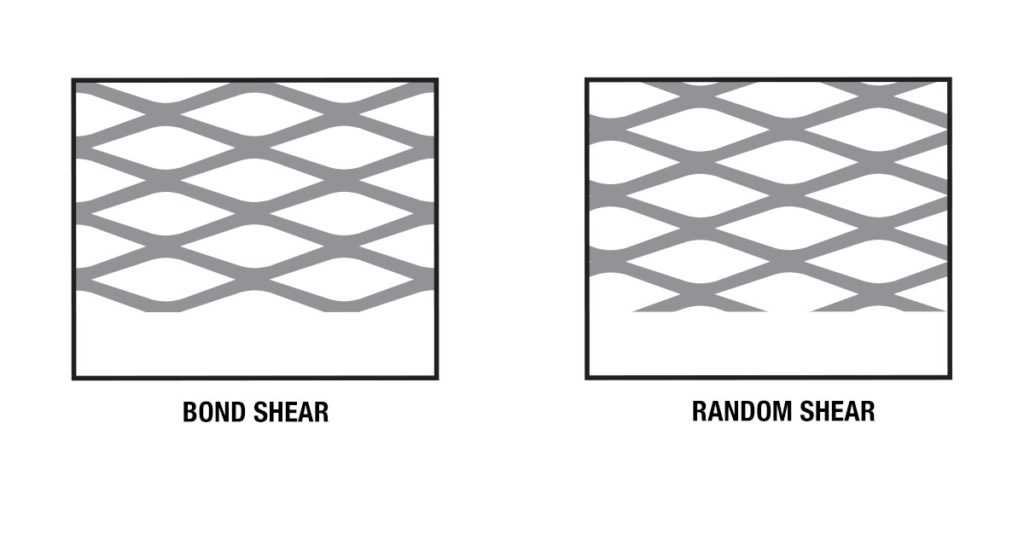

Shearing

Bond Shear: The expanded metal sheet is cut through the center of the bonds resulting in closed diamond at the edge of the sheet.

Random Shear: The expanded metal sheet is cut through diamonds resulting in partial diamonds at the sheet’s edge. The partial diamonds result in exposed strands that are very sharp and should be protected with U-Edging or framing.