Trench & Inlet Systems

Product Overview

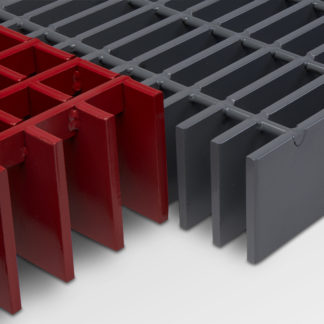

Grating Pacific trench and inlet systems combine our most popular gratings and embed frames in a complete set for economic, simple installation on construction projects. Systems are available in standard duty for pedestrian loads and heavy duty for demanding vehicular traffic.

- Multiple bar spacings to address specific applications

- Various frame profiles to match edge conditions

- Standard plain surface, galvanized finish

Options are available for slip-resistant surfaces or bolted grates.

Types of Trench & Inlet Systems

Standard Duty

Type “S”

Designed to support pedestrian loads, type “S” grates are manufactured from welding grating with durable 3/16″ (min.) thick bearing bars. Open area of nearly 80% allows for fast clearing of moisture and run off.

Type “SA”

Standard duty type “SA” grates are designed to conform with strict ADA spacing requirements. Open area of 68% allows for drainage and ventilation while maintaining a safe traffic surface.

Type “SP”

Type “SP” grates comply with ADA spacing requirements. Additionally, the 1/4″ maximum clear opening between the bearing bars makes these grates desirable in areas subject to pedestrian traffic where high heeled shoes are common.

Heavy Duty

Type “H”

Type “H” grates are manufactured from stout 3/8″ (min.) thick bearing bars and designed to serve truck and forklift loads. With nearly 70% open area, these products are ideal for parking lot and highway drain applications.

Type “HA”

Heavy Duty type “HA” grates are ADA conforming, similar to type “SA” above. These grates are additionally designed to support forklift and vehicular loads.

Type “HP”

Heavy Duty type “HP” grates are similar to type “SP” above, with the exception that these grates are additionally designed to support forklift and vehicular loads.

Bolting Options

Trench and inlet systems are manufactured as component products with grates easily removed for clearing debris. Often, security concerns or traffic conditions dictate that the grates must be bolted to the framing. When this option is specified, weld lugs or countersunk lands are installed on the grates and the bolt is installed below the traffic surface of the grating. For high security applications, tamper-resistant fasteners are available.

Bolted Grates with Weld Lugs

Tamper-Resistant Bolt with Weld Lug