Introduction & Specification

Specification Criteria

At Grating Pacific, our goal is to supply quality products that provide continued service and value to end-users. With that in mind, when specifying metal bar grating for your next project, it is important to consider the following factors:

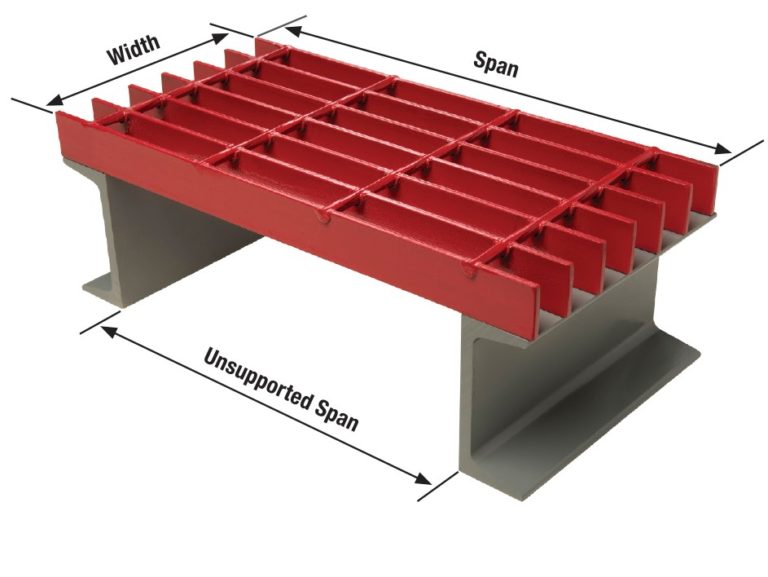

- Service load required and acceptable deflection

- Unsupported clear span

- Walking surface

- Banding and trim

- Finish

Service Loads

The load tables within this website provide load and deflection criteria for most common applications. These tables provide a concise reference to aid in the selection of the appropriate bearing bar size and spacing for the intended application.

Pedestrian loads are commonly analyzed with uniform and concentrated loads. For pedestrian comfort, deflection is typically limited to 1/4″.

Heavy duty and vehicular load tables are presented for specific load conditions with deflection limited to the lesser of 1/8″ or L/400.

If your application is not addressed by the load tables found in this website, please contact Grating Pacific for assistance selecting the product most appropriate for your application.

Surface Options

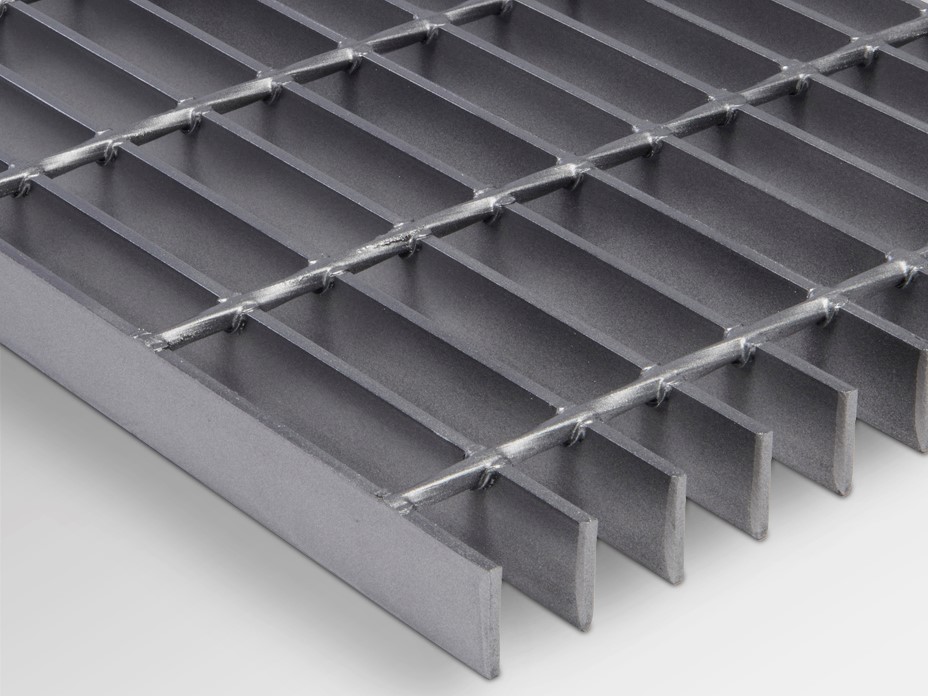

Plain Surface

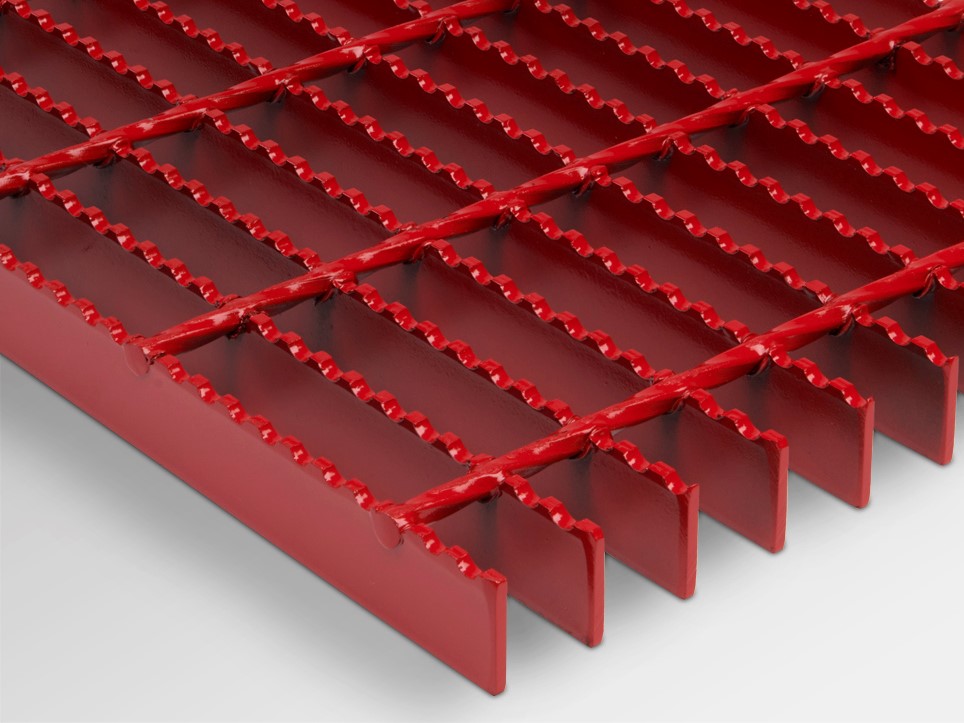

Serrated Surface

Preferred for applications where moisture or fluids cause the walking surface to become wet and slippery.

OnGrip™ Surface

Durable slip-resistant walking surface provides enhanced slip-resistance for applications in the public way.

Finishes

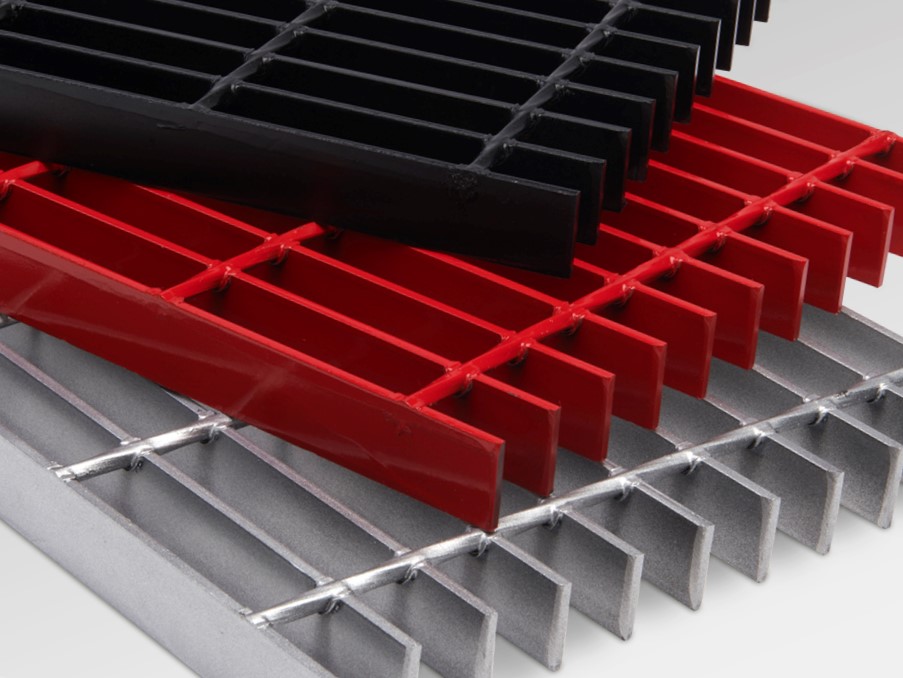

Steel products are commonly provided with one of three finishes: bare steel (no finish); painted with one coat of manufacturers red, black, or silver paint; or hot dip galvanized in accordance with ASTM A123.

Aluminum products are offered mill finish with optional chemical cleaning or anodizing also available.

Stainless Steel products typically require secondary cleaning due to discoloration that occurs during welding and fabrication. Commercial cleaning, passivation, or abrasive blasting can provide a uniform matte surface while electro-polishing leaves a bright stainless finish.

All products can be provided with specialty finishes including enamel or epoxy paints, or powder coating. When considering specialty finishes, contact Grating Pacific for consultation.

Anodized Aluminum Grating: clear or bronze finish

Banding

The open ends of the grating may be banded to provide additional transverse stiffness and a finished architectural appearance. Achieved by welding a flat bar, similar in size to the bearing bars, to the cut ends, banding enhances safety and should always be specified when gratings are designed to be removable.

Banding can reduce impact stress by transferring load to adjacent bearing bars and should always be specified when gratings are subject to vehicular loads. Further banding descriptions and welding standards can be found here.