Flattened Expanded Metal

Fabrication

Our fabrication teams are highly trained and ready to shear, form, roll, frame, or otherwise customize any expanded metal order as specified by the customer. These services can be provided to a single sheet or turnkey projects depending on customer requirements. Engineering and layout services are also available.

Shearing

When shearing sheets of expanded metal, it is important to specify desired end margins, random sheared or bond sheared. Random shearing results in open diamonds that have exposed strands that are very sharp and should be protected with edging or framing. Bond sheared panels are sheared through the center of bonds resulting in closed diamonds at the panel’s edge.

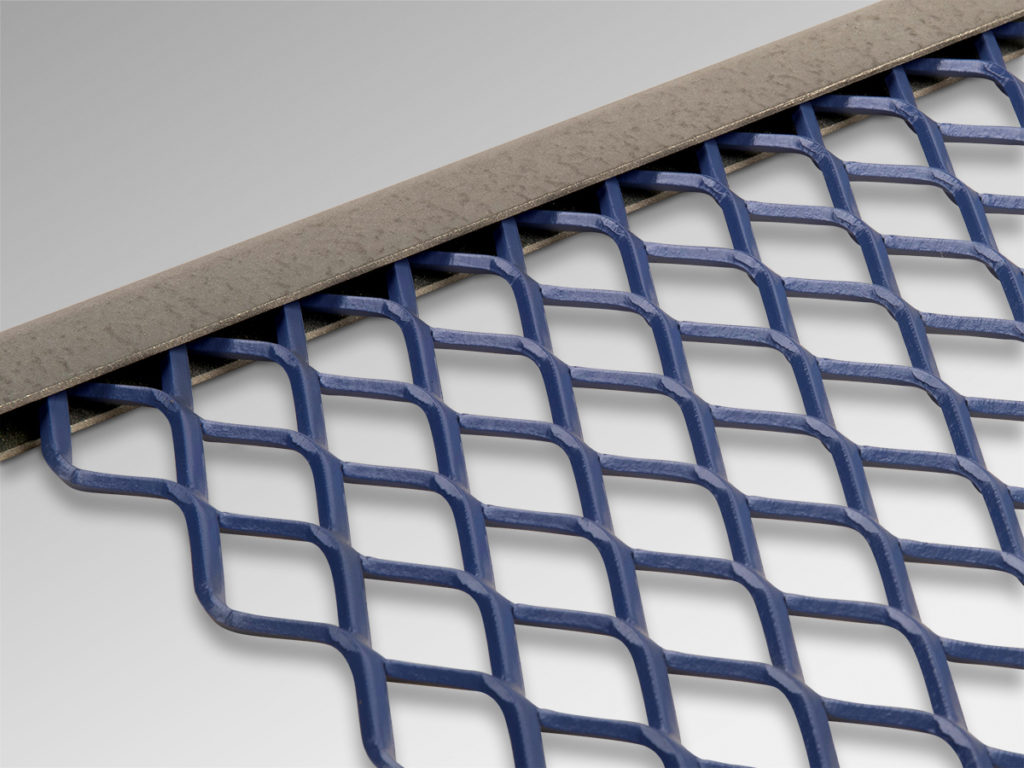

U-Edging

U-Edging provides a uniform and attractive appearance to the panel. As the name implies, a formed “U”-shaped strip of metal is welded to the edge of a panel as specified by the order. Benefits of U-edging include a framed appearance and protection from sheared edges.

U-Edging is available from stock in 10′-0 or 12’-0 lengths of carbon steel, aluminum, or stainless steel. Alloy dependent, openings range from 1/16” to 1/2” with 1” overall width. Custom sizes are available on special order.

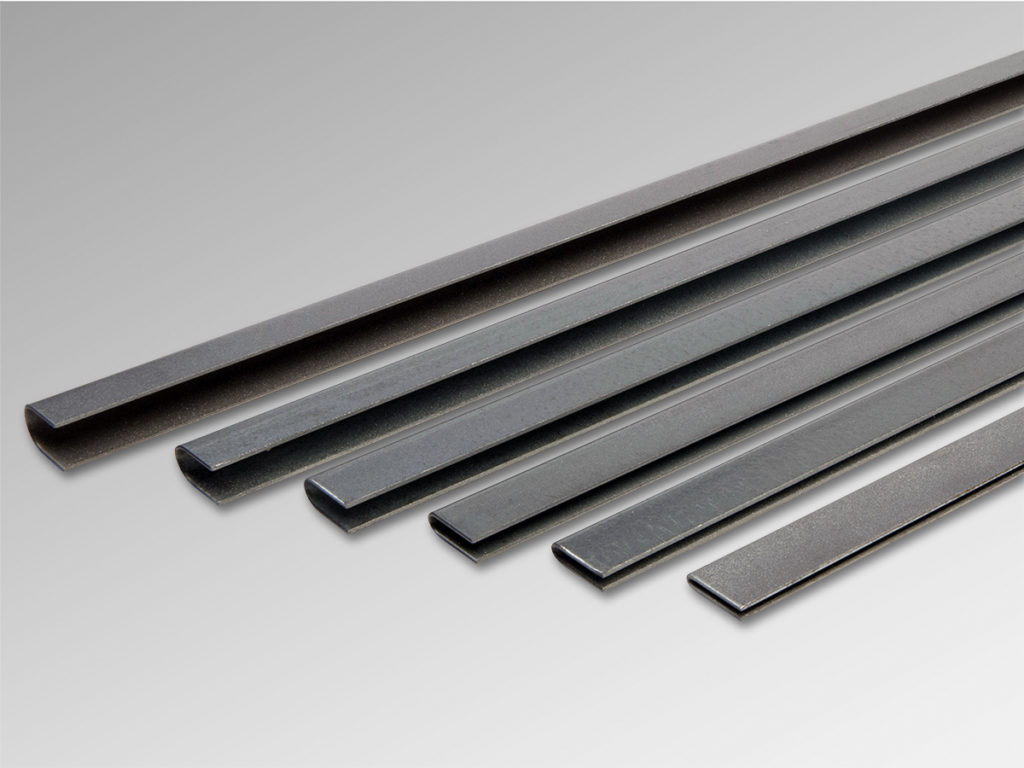

Stock carbon steel U-Edging includes:

- Part No. U-063-S, 1/16” opening

- Part No. U-125-S, 1/8” opening

- Part No. U-188-S, 3/16” opening

- Part No. U-250-S, 1/4” opening

- Part No. U-375-S, 3/8” opening

- Part No. U-500-S, 1/2” opening

Angle & Custom Framing

Angle Framing adds rigidity and a uniform, geometric look to the panel. Popular for infill panels, partitions, or equipment guards. Perimeter angles are available in a wide range of sizes, each offering alternative strengths and appearance.

In addition to angle framing and U-edging, our talented fabrication specialists have experience with a wide range of custom designed framing options. Nested flat bars, tube framing, and channel framing can be designed and fabricated to complement adjacent architecture.

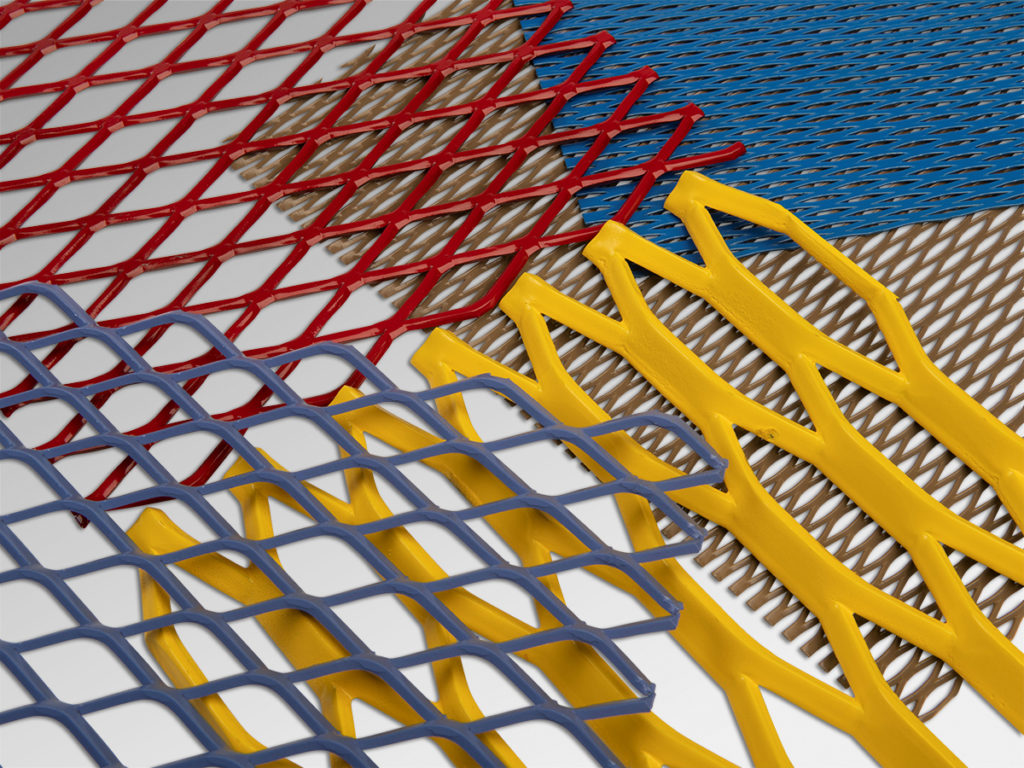

Materials & Finishes

All expanded metals are available in a variety of metals; carbon steel, stainless steel, and aluminum. All products are lightly oiled during manufacture and stocked mill finish. If finish coatings will be applied, the metal should be cleaned prior to the application.

Carbon steel expanded metals can easily be painted or galvanized to enhance corrosion resistance. Aluminum products can be anodized, or epoxy coated. Stainless steel products can be electroplated to provide for a bright finish or abrasive blasted to provide a uniform matte finish.