Architectural Wire Products

Materials Available

Carbon Steel

Plain low carbon steel typically ranging from C1006 to C1012 alloy, drawn from rod. Combines strength and weldability with economy.

Galvanized Before Weaving / Welding

Carbon steel coated with a light layer of zinc during the manufacturing process. Adequate corrosion resistance is provided for most indoor applications, but not recommended for outdoor installations.

Galvanized After Woven / Welding

Carbon steel coated with a heavy layer of zinc after the manufacture of the mesh. Excellent for long term corrosion protection.

High Carbon Steel

Abrasion resistant steel used for applications facing significant wear such as media filtering or sorting. Abrasion resistant steel can be difficult to weld, consider mechanical fastening to supporting structure.

Stainless Steel

Commonly manufactured in 300 series alloys. Type 304 is most popular, but also available in types 309, 310, 316, 321 & 347. Series 400 alloys are also available on special order.

Aluminum

Lightweight and mildly resistant to corrosion, aluminum alloys are readily available. Alloy 1350 is most common and can be easily welded and anodized. Also available are alloys 5056 and 6061.

Nickle Based Alloys

Inconel 600, Monel 400, Nichrome V and Hastalloy C276 offer specific characteristics desirable in specialized environments.

Specialty Alloys

Copper based alloys, bronze, brass and titanium are also available for all woven products. Contact our sales engineers for assistance in selecting the proper specialty alloy for your application.

Note: Unless otherwise specified, all products offered are in a bare, mill-finished condition. Secondary finishes may sometimes be desired to protect the mesh or to enhance a desired performance or aesthetic. We can facilitate the process of secondary finishes such as passivating, powder coating, and plating if required.

Wire Mesh Spacings

Woven and Welded Wire Cloth are identified and manufactured based upon their mesh sizes (wire spacings). These mesh sizes are expressed in either center-to-center wire spacings, clear opening between the wires, or mesh count.

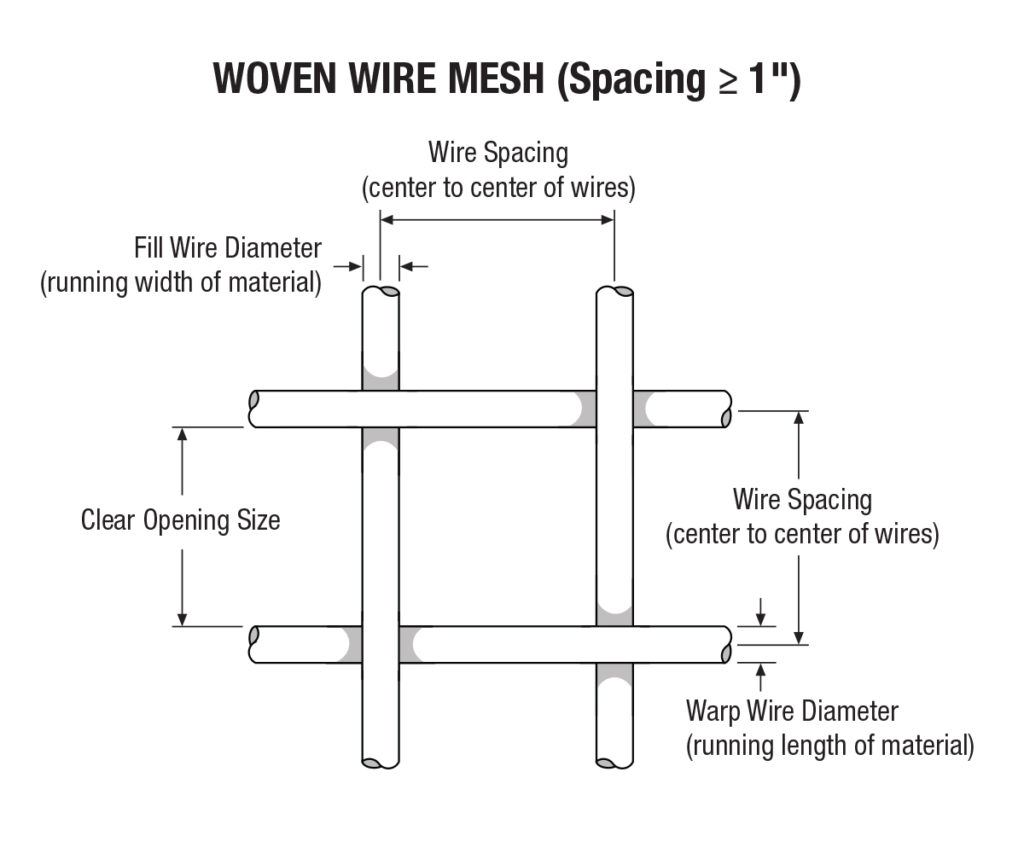

Woven Wire Mesh

Woven products are specified as either Mesh, meaning center-to-center of wires, or Clear Opening which indicates the opening between the wires.

Example 1 – Mesh: 1” square mesh woven wire produced with .135 wire will be manufactured with the wires spaced 1” on center, resulting in a .865 clear opening.

Example 2 – Clear Opening: 2” clear square opening woven wire mesh produced with .250 wire will be manufactured with the wires spaced 2-1/4” on center, resulting in a 2” clear opening.

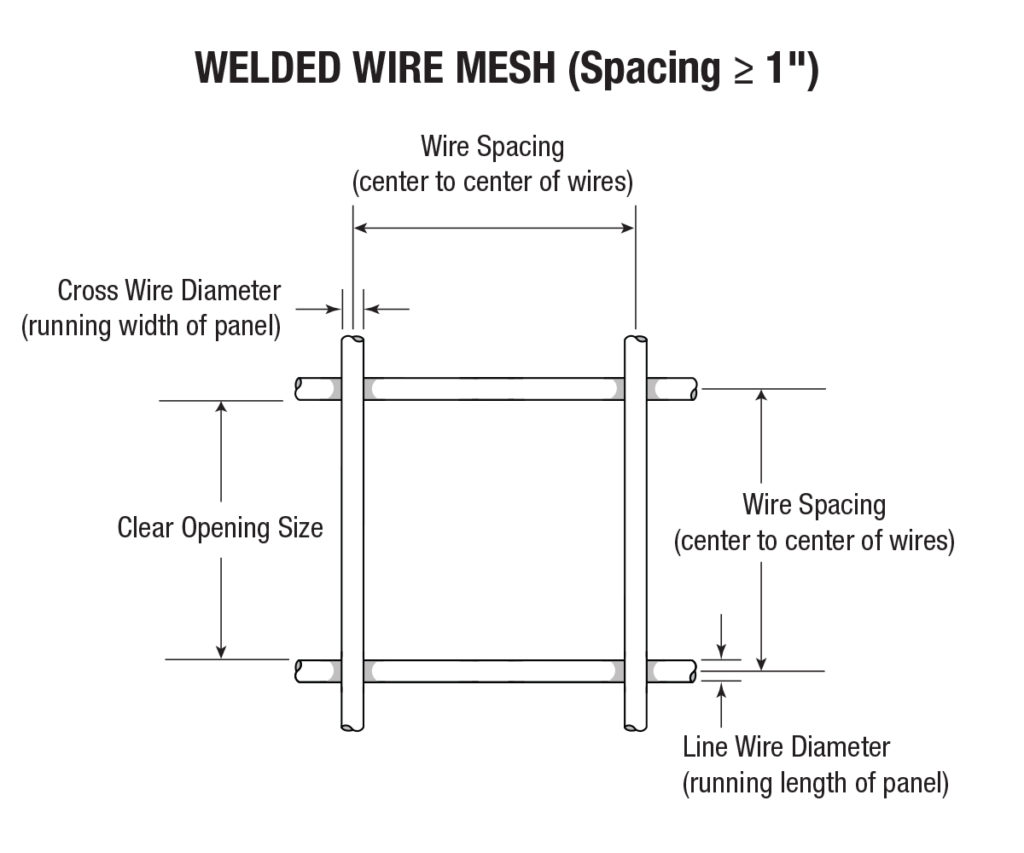

Welded Wire Mesh

Welded products, with openings equal to or exceeding 1”, are specified based on the center-to-center spacing of the wires.

Example: 2” square welded wire mesh produced with .250 wire will be manufactured with the wires spaced 2” on center, resulting in a 1-3/4” clear opening.

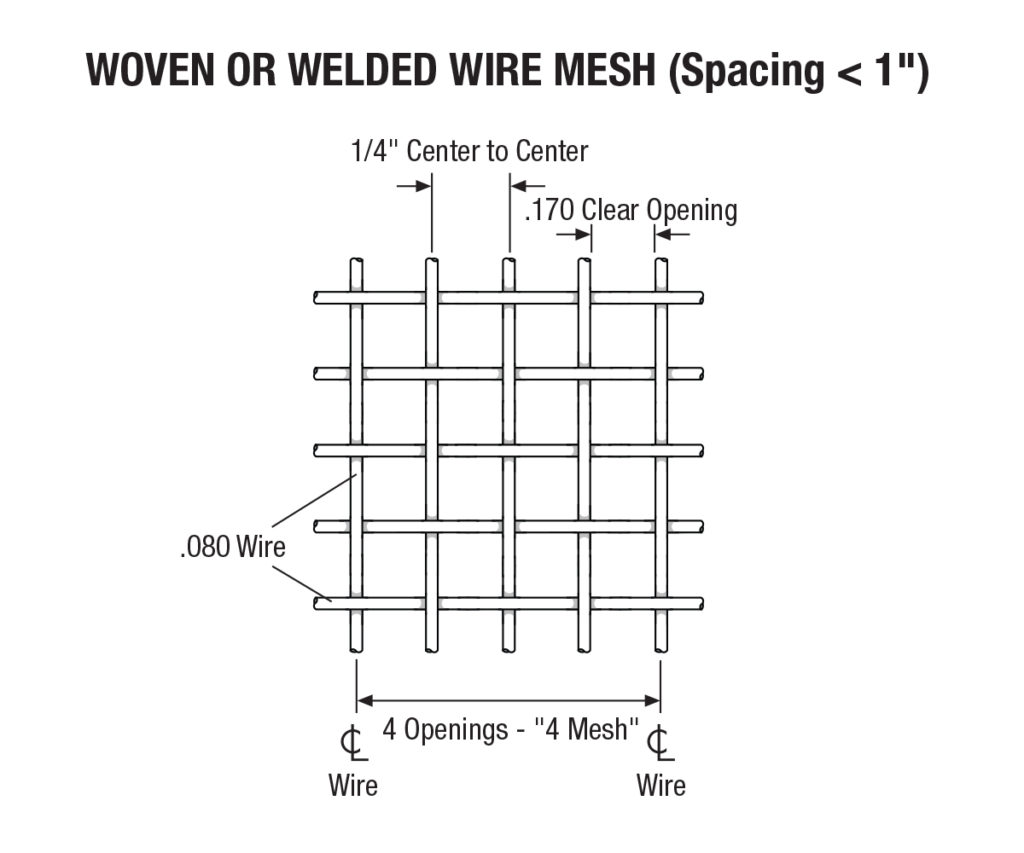

Woven or Welded Wire Cloth – meshes less than 1” on center

Wire Cloth and Hardware Cloth, with mesh sizes less than one inch can be specified three ways. For the material illustrated, which is a Wire Cloth with .080 wires spaced at 1/4″ on center, the product may be specified in any of the following manners:

- Mesh Count: 4 Mesh, .080 wire

- Center-to-Center Spacing: 1/4″ mesh, center-to-center, .080 wire

- Opening Size: .170 clear opening, .080 wire